Browse our range of reports and publications including performance and financial statement audit reports, assurance review reports, information reports and annual reports.

Management of the M113 Armoured Personnel Carrier Upgrade Project

The objective of the audit was to provide an independent assurance on the effectiveness of the management of the upgrade of the M113 fleet for the Australian Defence Force (ADF). The audit sought to identify the initial capability requirements and approval process; analyse the contract negotiation process; and examine the management of the project and contracts.

Summary

Background

1. The M113A1 family of vehicles was introduced into service in Australia in the mid 1960s with additional vehicle variants added into the fleet until 1979. The M113 is a lightly armoured aluminium bodied, fully tracked vehicle available in a range of different variants. The most common variant in the Australian Army's M113 fleet is the armoured personnel carrier, which is used to carry troops and their equipment. Throughout its life, operational deficiencies have been identified with the M113 fleet and a number of reviews and proposals for upgrades of the existing fleet and the procurement of a new fleet have been considered by Government. However, the Australian Army's fleet of M113s currently remains in its original mid 1960s M113A1 standard. 2

2. The upgrade project for the M113s essentially comprised of two major stages. The first stage commenced in 1992 and culminated in the awarding of a contract in mid 1997 for a minimum vehicle upgrade. In accordance with the 2000 Defence White Paper, a second stage of the project commenced in 2002 for a major upgrade of the M113 fleet of vehicles.

3. In July 1992, Army proposed a minimum upgrade of the M113 fleet to improve firepower, night vision, fighting, habitability and survivability capabilities. Phase 1 was to consist of upgrading 537 vehicles to an A2 3 standard to be delivered from 1996 to 1998 at an approved cost of $39.9 million (April 1993 prices). Phase 2 of the Project was to upgrade the remaining vehicles to the same standard with final delivery to be in late 2000.

4. The Minimum Upgrade Project was to procure upgraded turrets (based on an existing design) with weapons and day/night sights; cooled drinking water systems; quick change barrel machine guns; A2 standard suspension kits; spall curtains; 4 and engine cooling kits. A Prime Contract for Phase 1(a) was signed with Tenix 5 in May 1997 to procure new or modified T50 turrets 6, cooled drinking water systems and for the installation of the other components. The other components were to be installed by the Prime Contractor, but were procured by Defence under separate Phase 1 contracts.

5. After the acquisition of most of the Phase 1 component parts (the turret and cooled drinking water systems being provided under the Phase 1(a) contract were yet to be delivered), the Phase 1(a) Prime Contractor provided Defence with an unsolicited proposal in late 1997—early 1998 to combine Phase 1 and 2 and upgrade 360 vehicles to an M113AS3 standard. 7

6. The Prime Contractor's proposal identified that this option would provide $30 million in savings for Defence. Defence subsequently decided to sole source the combined upgrade to the Contractor. To do this, Defence suspended the Phase 1(a) Prime Contract in June 1999 and the Prime Contractor developed a number of Contract Change Proposals (CCPs) to develop a new contract which represented the second stage of the project.

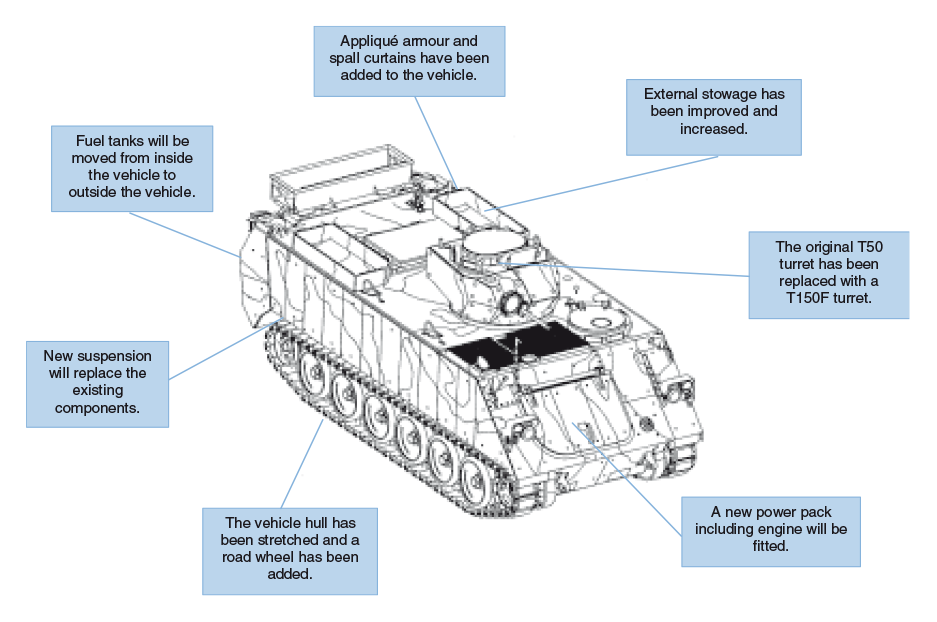

7. The Major Upgrade Contract was signed in July 2002 for the supply of 350 vehicles at an AS3 and AS4 8 standard at a cost of $388 million (Dec 2001 prices). The upgrade will include the assembly of components with the M113A1 hulls (see Figure 1). The vehicles contracted for are substantially different to that envisaged in Phase 1 of the Project.

8. The M113A1 vehicles have a written down value of $73 million which equates to a carrying value for each vehicle of some $98 000. The 350 vehicles to be upgraded by the M113 Upgrade Project will cost (under the Major Upgrade Contract) around $1 million each depending on variant. 9

Figure 1: Assembly of major upgrade components under the Major Upgrade Contract

NOTE: This diagram is representational only, it does not include Government furnished equipment reclaimed from A1 vehicles or manufactured items under the Commercial Support Program Contract.

Source: ANAO interpretation of Defence documentation.

Audit approach

9. The objective of the audit was to provide an independent assurance on the effectiveness of the management of the upgrade of the M113 fleet for the Australian Defence Force (ADF). The audit sought to identify the initial capability requirements and approval process; analyse the contract negotiation process; and examine the management of the project and contracts.

Overall audit conclusion

10. The ANAO found that the Project has undergone extensive scope changes and chronic schedule delays since its inception. The M113 family of vehicles was originally to undergo a minimum upgrade to improve firepower, night vision, fighting, habitability and survivability capabilities. The Project changed and is now to perform a major upgrade of 350 M113 vehicles comprising about two thirds of the current in service fleet. The M113 Major Upgrade Project was approved at a cost of $552 million in June 2002. The ADF is yet to receive any upgraded vehicles. The upgraded vehicles will not start to enter into service until late 2006 with the last vehicle to be delivered in late 2010. The vehicle has a planned end of life of 2020. The new contracted vehicle, while consistent with the currently approved project scope, is substantially different to the vehicle originally envisaged by the Army.

11. The Minimum Upgrade Phase of the Project suffered from poor project management practices; ineffective project planning; inadequately defined project objectives; and suffered technical problems with the T50 turret. Combined with an inability to successfully integrate the components of the vehicle, this resulted in a failure to deliver capability to the ADF.

12. The ANAO found that the three year delay between the approval to combine the phases in June 1999 and entering into a contract for the major upgrade of 350 M113 vehicles was characterised by an inability of Defence to successfully manage changes in requirements. By February 1999, before Contract suspension, some $9.7 million had been spent from the Minimum Upgrade Prime Contract. After the decision to sole source, some $27.8 million was paid for tasks performed by the Contractor towards developing an acceptable combined upgrade proposal and for postponement costs.

13. The ANAO considers that the new Major Upgrade Contract, executed in July 2002, has provided an improved framework for Defence to advance the Project. The System Program Office10 is taking an active role in managing the Project. Nevertheless, there is still some doubt as to whether the upgraded vehicles will meet their in-service date of late 2006. The Contractor is now putting in place a process of fast tracking production whereby they commence producing vehicles at their own risk before they have passed Defence formal testing. The ANAO considers that this approach involves a high level of risk for the delivery of Army capability. Notwithstanding the Contractor's liability for this risk, it will require close management by both the Contractor and Defence.

Key findings

Minimum upgrade project (Chapter 2)

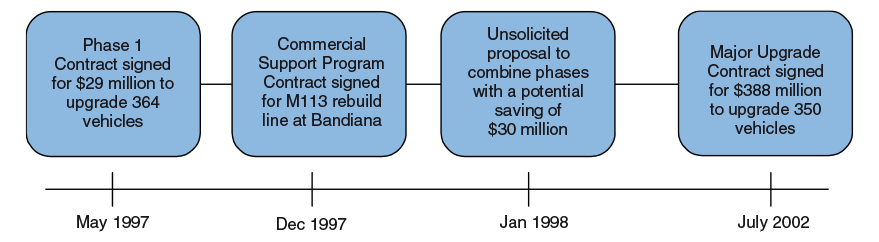

14. In 1995 Defence reduced the planned scope of Phase 1 of the Project to modify 364 vehicles (reduced from 537) with a total approved budget of $49.99 million. In early 1995, Defence released a Request for Tender for the Phase 1(a) Prime Contract to nine Australian companies and eight responses were received by late June 1995. The Tenix bid was assessed as being the most compliant and the Phase 1(a) Prime Contract was signed on 5 May 1997 for $29.19 million (Dec 1996 prices) including an advance payment of $4.21 million (14.4 per cent).

15. By May 1997, separate contracts for the Phase 1 component parts to be provided to the Phase 1(a) Prime Contractor as Government furnished equipment had been signed (see Figure 2). All of the Phase 1 Contracts were closed by mid 2000 with the exception of Phase 1(a).

Figure 2: Conctractual timeline

Source: ANAO interpretation of Defence documentation.

16. Six months after Phase 1(a) Contract signature the Prime Contractor approached Defence with a proposal to combine Phases 1 and 2 of the upgrade project together with a Commercial Support Program Contract which they already held with Defence. The proposal stated that through a sole source acquisition strategy Defence could achieve a number of efficiencies (including meeting an in-service date some two to three years earlier then planned) and make a saving of approximately $30 million. The ANAO considers that no such saving will occur.

17. Defence documentation shows that the four prototype vehicles did not include all Phase 1 components (see Table 1) as stipulated in the Phase 1(a) Contract. The ANAO considers that it would have been prudent for the prototype vehicles to include all component parts and appropriate integration.

18. As outlined in Table 1, the major components of the Phase 1 Minimum Upgrade, namely Phase 1(a) costing $29.19 million was largely incomplete at the time of the audit with no turrets produced and the drinking water system removed from the scope of the Contract. Defence advised the ANAO in November 2004, that some items have been issued to units for use with the existing M113A1 fleet, whilst others have been placed in storage at Bandiana (see Table 1). 11

Table 1: Phase 1 components status: March 2005

Source: ANAO interpretation of Defence documentation.

19. Prototype turret sights provided for testing in late 1999 (some five months late) did not meet specification and were not accepted by Defence. An alternative sight was subsequently provided by the Contractor. The Contractor advised the ANAO that ‘The prototype day/night sight was leading edge electronic camera technology (electro-optical sight) that at that time in its life cycle was immature.' No liquidated damages were subsequently sought relating to the late delivery of the prototype sight. The trials also determined that the cooled drinking water system should not be continued with further.

20. The Phase 1(a) Prime Contract, signed in 1997 for a turret and the installation of Government furnished equipment, was not achieved and Defence subsequently sole sourced the new Major Upgrade to the same Prime Contractor.

Contract suspension and interim phase (Chapter 3)

21. In May 1998 the then Minister for Defence noted Defence's decision to sole source Phase 2 to Tenix. It was subsequently decided to combine the phases through firstly suspending the Phase 1(a) Contract through CCP One and then have Tenix develop a series of CCPs to develop the Major Upgrade Contract.

22. The CCPs were developed by Tenix and Defence as part of an integrated product team. Rather than follow the normal procedures of developing a detailed operating requirement, statement of requirement and top level specification, Defence relied on the Contractor's involvement in the integrated product team. The ANAO considers that the implementation of the Defence Procurement Review of 2003 (Kinnaird Review) should remediate this situation in future projects.

23. During the evaluation of CCP Two, it became apparent that the integrated product team had not provided the level of visibility into the process as had been expected. CCP Two showed that combining the project phases would be more expensive than expected and the offer itself had a number of problems. CCP Two and Three were subsequently declined.

24. A further CCP for a Project Definition Study and Mockup Vehicle Phase was provided to Defence in November 2000. The ANAO notes that the scope of the CCP was the result of joint exploration by Defence and the Contractor and did not follow the normal process of a formal request then subsequent evaluation. Defence stated that the reason for not following the normal process was that the CCP was to reduce the risk of the project and was therefore low risk itself. The CCP was for a total cost of $9.71 million.

25. The ANAO considers that this is a real variation to the Contract and should have had the concurrence of both the Minister for Defence and the Minister for Finance and Administration. While the Minister for Defence was asked to and did note the change, neither Minister was asked for or gave their concurrence for this expenditure. Defence advised the ANAO in July 2005 that:

contrary to the opinion expressed in the audit report, Defence believes that the change in contract scope referred to … was within the broad revised project scope that had been endorsed by Cabinet in the Defence White Paper and Defence Capability Plan. The contract change was for an activity that was necessary to deliver the revised capability endorsed by Government vide these documents and was well within the project funding approved at that time. Hence the contract change did not require a further approval by the two Ministers.

26. The ANAO notes that in accordance with Defence policy any change (whether within the broad revised project scope or not) over $8 million requires the concurrence of both the Minister for Defence and Minister for Finance and Administration.

27. The original sole source strategy was based on labour being offered at the Commercial Support Program rates only, however the offered price of the Contract was based on labour plus overheads. Defence determined that this added roughly 25 per cent or $5 million to the base rate. The ANAO considers that labour rates have changed significantly since the Commercial Support Program Contract was signed and that there are now three separate labour rate categories each with varying average hourly labour rates. Additionally the ANAO considers that only about 35 per cent of work on the vehicle will be performed under the Major Upgrade Contract with the remainder to be completed under the Commercial Support Program Contract at Defence's Bandiana facility.

28. The ANAO notes that of the original $4.21 million mobilisation payment made in mid 1997 only $970 000 has been offset against deliverables in the Contract by March 2005. The ANAO considers that the remaining $3.24 million is a debt owed to the Australian Government which should be returned by the Contractor. In addition, the ANAO considers that there is an opportunity interest cost foregone to the Australian Government estimated at some $1.34 million, as of mid 2005, as a result of the residual mobilisation payment.

Management of the new contract (Chapter 4)

29. The M113 Major Upgrade Project was approved at a cost of $552 million (2002 prices), including previously approved funding of $62.13 million. Of this, $388 million is for the Major Upgrade Contract and the residual consists of items such as project costs, contingency and a lump sum set aside for initial logistics support. The estimated expenditure of the Project to 30 June 2005 is $187 million.

30. By early 2005, the Contractor was late in providing a revised schedule to the Project Office against which the Contractor's performance could be assessed. The production of some variants would slip up to six months however the Contractor has advised that the in-service date would remain as November 2006. Part of the problem of producing a schedule was due to performance issues concerning the excessive engine heat. This has not yet been resolved however, the Contractor advised that:

solutions have been identified to resolve heat issues. The Contractor has commenced conducting internal testing to satisfy itself that the solution meets the contract requirements. This issue has resulted in schedule delays but is not a reason for failure to produce a revised schedule.

31. The Contractor has advised Defence that they will be fast tracking some elements of initial production vehicle testing in order to meet the scheduled in-service date. Testing of the initial production vehicles was to occur in a linear fashion with Defence conducting the Reliability Qualification Test and a Production Readiness Review before the Contractor was given authority to move to full rate production.

32. The new schedule shows that the Contractor will be conducting their own Reliability Qualification Test (before Defence) and proceeding to full rate production based on these results. This revised program shows that not only is the schedule some eleven months later than originally planned, production will occur before the necessary Defence sign off. Whilst the risk will sit in the main with the Contractor, it is still a high risk option for Defence.

33. Defence advised the ANAO in June 2005 that: ‘under the contract arrangements prior to mid 2004, it is clear there was uncertainty between Defence and the Contractor over how the GST component of a tax invoice should be shown and calculated.' Section 9–85 of A New Tax System (Goods and Services Tax) Act 1999, requires that the value of taxable supplies be expressed in Australian currency. Contractor invoices from January 2002 to June 2004 were not expressed in Australian currency and so were not compliant.

34. The Contractor now lodges compliant GST invoices for foreign exchange claims. However, they are based on the spot retail sell rate on the day of the invoice. The retail rate is for payments usually up to $A 25 000 and the rate more generally used for large overseas currency payments is the wholesale rate. The ANAO calculates that on average Defence paid a difference of 80 basis points 12 using the retail rate rather than the wholesale rate.

35. The Major Upgrade Contract contains the provision for two mobilisation payments equalling $80 million. The first $40 million was paid to the Contractor in mid 2002 with the second due when the Contractor passes the Production Readiness Review. The mobilisation payment is offset against contract deliverables however, when the second payment is to be made, at the successful completion of the production readiness review, only $9.67 million will have been offset against the first mobilisation payment and will not be fully offset until late 2010.

36. Defence is currently claiming liquidated damages for two areas of delay by the Contractor. Defence have advised that an amount of $23 000 has been calculated up to 13 September 2004 for the provision of Integrated Logistic Support data and plans and production of initial production vehicles.

Agency response

37. The ANAO made three recommendations directed towards the improvement of project and contract management. Defence agreed with all recommendations.

Footnotes

1 There are 766 M113A1 vehicles currently in the Australian Army fleet. Whilst it was originally planned to upgrade the entire M113 fleet over two phases, the number of M113s still in service has reduced since 1992. As at 9 February 2005, only 520 vehicles are in service (other vehicles are no longer in service; are on loan; or in a reserve/maintenance pool).

2 M113A1: Original vehicle purchased in mid 1960s to 1979 with no upgrades (some having undergone repair and overhaul at 25 000km).

3 M113A2: Minimum upgrade with new components such as spall curtains, suspension, engine cooling, turret and machine gun.

4 Spall curtains are ballistic curtains attached to the interior of the vehicle to protect the occupants from metal spall fragments.

5 The Prime Contractor, originally called Transfield Defence Systems was re-named Tenix Defence Systems in November 1997 after the Defence arm of the company split. More recently it has become known as Tenix Defence.

6The T50 turret was an American design and was fitted in the 1960s. It became the standard Armoured Personnel Carrier turret.

7 M113AS3: Major upgrade to an A2 standard plus power pack and drive train.

8 M113AS4: Major upgrade to an AS3 standard with stretch technology.

9 This amount does not include the additional expenditure being contributed to the M113 Upgrade Project under the M113 Fleet budget and the Commercial Support Program Contract. The M113 Fleet budget and activities performed under the Commercial Support Program Contract are generally used for the purposes of maintenance and repair of the in service M113 Fleet.

10 The Defence Materiel Organisation manages major capital acquisition projects through 46 System Program Offices around Australia and was established as a prescribed agency on 1 July 2005. The M113 Major Upgrade Project is managed within the Tracked Manoeuvre System Program Office in Melbourne.

11 Defence further advised the ANAO that Government furnished equipment items purchased during Phase 1 that are stored at Bandiana were recently re-catalogued as kits and recorded on the Standard Defence Supply System.

12 Using a weighted average over a 168 day period, this equates to approximately $15 500.