Browse our range of reports and publications including performance and financial statement audit reports, assurance review reports, information reports and annual reports.

Acquisition of the ABRAMS Main Battle Tank

The objective of the audit was to assess the effectiveness of management of the procurement of a major, replacement capability for the Australian Defence Force (ADF) by the DMO, and Defence. The audit reviewed the initial capability requirements and approval process; analysed the acquisition agreements for elements of the project; and examined the interim through-life support arrangements being put in place to support the capability.

Summary

Introduction

1. The Defence Materiel Organisation (DMO) Project Land 907 (the project) is delivering a modern tank capability to the Australian Army, to replace the ageing Australian Leopard AS1 tanks. The project will deliver 59 M1A1 ABRAMS AIM (ABRAMS Integrated Management)1 Main Battle Tanks (ABRAMS), seven M88A2 Hercules Tank Recovery Vehicles, six gunnery and one driver training simulators, 14 tank transporters,2 eight fuel trucks and a logistic package of support equipment, spare parts, ammunition, facilities and initial training.

2. The total project budget, as of February 2007, is $555 million. The acquisition of the central elements of the capability was based on the delivery of ‘off-the-shelf'3 equipment, using a Foreign Military Sales (FMS) agreement, with the United States (US) Government, representing a low risk to Defence.4

3. The September 2003 Defence Procurement Review (the Kinnaird Report) proposed that, pending the full implementation of the two-pass approval system, Government's consideration of the November 2003 Defence Capability Plan 2004–14 could constitute First-Pass Approval of projects contained therein. The Land 907 Phase 1 budget was considered by Government in October 2003 as part of a submission by Defence, and subsequently approved for entry to the Defence Capability Plan 2004–14.

4. In early March 2004, Government agreed with the proposal to exempt projects published in the Defence Capability Plan with a 2003–04 or 2004–05 year of decision from the First-Pass Approval process, which included this project. Those projects that were recipients of the exemption were authorised to progress directly to Second-Pass consideration. The strengthened two-pass approval system was to be fully implemented for projects with a 2005–06 year of decision or later.

Acquisition arrangements

5. The ABRAMS is a complete rebuild of the M1A1 tank, whereby they are completely disassembled, inspected, and where necessary refurbished, and reassembled. The AIM process takes an older combat system, and replaces it with a digitised, integrated combat system. During the AIM rebuild process, 86 per cent of the component parts of each Australian tank are replaced as new, and the remaining 14 per cent are returned to the original equipment manufacturer for inspection, and if required, replacement prior to reinstallation.5

6. In late June 2004, the DMO negotiated, and signed an FMS agreement with the US Government to deliver the tanks, and recovery vehicles, along with a range of support equipment. The prime FMS agreement represents some 57 per cent of the total project budget, with other major components of the project relating to repair parts (17 per cent) and facilities (six per cent).

7. Defence considers that acquiring items through an FMS Programme represents an attractive alternative to commercial acquisition methodologies where: the US Department of Defense has better bargaining power; economies of scale can be achieved by leveraging from other countries' orders; and it assures compatibility with, and long-term support from, the US Department of Defense.

8. In support of the prime FMS agreement (at an estimated value of US$ 302.95 million), a second FMS agreement, worth some two per cent of the total budget, is delivering the tank-borne equipment required to support a satellite based Battle Management System for the ABRAMS capability6. Off-platform capability associated with satellite communications for the ABRAMS Battle Management System is being provided separately by the Defence Chief Information Officer Group, and has suffered schedule delays.

Audit approach

9. The objective of the audit was to assess the effectiveness of management of the procurement of a major, replacement capability for the Australian Defence Force (ADF) by the DMO, and Defence. The audit reviewed the initial capability requirements and approval process; analysed the acquisition agreements for elements of the project; and examined the interim through-life support arrangements being put in place to support the capability.

Overall Audit Conclusion

10. The project to acquire the ABRAMS tank capability has effectively reduced acquisition and development risks by procuring equipment that is part of a fully developed ‘military off-the-shelf' US Government programme.7 In parallel, Defence did not vary the product performance specifications during the acquisition, which has served to ensure the delivery of the required capability on time, to budget, and to the required quality.

11. The project is being effectively managed by the DMO to deliver an improved, replacement capability for the ageing Australian Leopard AS1 Main Battle Tanks. The teamwork required to deliver the capability, incorporating multiple Groups within the DMO and Defence, has been successfully managed to ensure that the capability is likely to be delivered on schedule, to the Army, by July 2007. In doing so, the key elements associated with delivering fundamental inputs to capability8 were in place, and operational, to support individual training, and acceptance testing, as required.

12. As of the end of April 2007, the DMO had expended some $408 million on the project to acquire the 59 ABRAMS tanks, seven M88A2 Hercules Recovery Vehicles, 14 commercially contracted heavy tank transporters, eight fuel trucks, ammunition, the onboard elements of a Battle Management System, and supporting logistics and ammunition. The ANAO notes that delays have been associated with a separate, yet supporting Defence Chief Information Officer project to provide Army with a commercially sourced satellite communications facility for the Battle Management System. Army has reported that this delay has in turn delayed the Army's planned training programme.

Key findings

Source selection (Chapter 2)

13. In seeking project approval, Defence recommended the acquisition of the ABRAMS capability over all other options considered, primarily on the basis of proven operational survivability and cost. The ANAO reviewed the analysis undertaken as part of the preparation for Second Pass approval. The full suite of required Second-Pass documentation (which included: the Operational Concept Document; the Functional Performance Specifications; the Test Concept Document; and Acquisition Business Case ) had not been finalised at the time of Second-Pass Approval in March 2004.

14. In March 2005, the DMO proposed that the FMS agreement be extended to include a Battle Management System, which serves as a communication link showing, inter alia, the geographic location of friendly units on a battlefield. The selected system is one that was already manufactured by the US, and integrated to US Army ABRAMS M1A1 AIM tanks, thus reducing integration risks associated with adding the system to the tanks following the AIM process. The system is being treated as an interim system, and is not intended to interface with any existing ADF system. The first stage of the Battle Management System availability was scheduled for April 2007, however it has been delayed with a temporary service schedule to be provided in July 2007.

Acquisition management (Chapter 3)

15. The FMS Programme is a key means by which the Australian Government procures military goods and services, directly from the US Government. Once selected as a procurement method, the Australian Government is obligated to make payments, on demand, prior to the delivery of equipment from the US. To give effect to the FMS Programme, Australia is required to maintain a bank account at the US Federal Reserve Bank in New York, from which the US Department of Defense draws down progressive payments into a trust fund, from which contractors are paid. As of February 2007, the balance of the interest bearing Reserve Bank of Australia FMS bank account was US$ 207 million.

16. The first batch of tanks and recovery vehicles arrived in Australia in September 2006, following their use with training Australian instructors in the US. The six gunnery simulators and one driver training simulator have been delivered, and are in use training Australian Army personnel. Tank transporters and fuel trucks are being progressively delivered, and have been used to support tank training operations in Australia. The final delivery of tanks from the US occurred in March 2007.

17. The ANAO reviewed the risk management of the transportation of the first delivery of ABRAMS tanks and Hercules Recovery Vehicles in September 2006 from the US to Australia. The DMO did not fully analyse and document the risks associated with moving the tanks to Australia using commercial sea transport. A developed risk analysis of the commercial transportation of the first delivery of tanks, had it been undertaken, could have included consideration of utilising a costed insurance quote in the event of loss of the shipment at sea.

18. The declared Australian Customs Service (Customs) values associated with the importation of the first batch of 18 tanks, and five Hercules Recovery Vehicles in September 2006 were reported as $43.09 million, which was not representative of the purchase values of the shipment. The Customs Declaration Form, submitted as part of the importation process for the shipment, understated the value of the 18 imported tanks and the five transported Hercules Recovery Vehicles by some $91.56 million. The ANAO also notes that there was a corresponding misstatement associated with the DMO Business Activity Statement for the period, and of the monthly importation figures calculated by the Australian Bureau of Statistics for national accounts purposes for international trade in goods and services. The Project Office advised the ANAO in February 2007 that a revised N10 Import Declaration had been submitted to Customs, where the value of the imported goods has been recalculated to be $134.65 million.

19. Provision of the Heavy Tank Transporters, and Tactical Fuel Trucks is being managed via commercial contracts with Australian suppliers, which are cumulatively worth some $22 million. The relevant contractors have delivered these capabilities to schedule.

Through-life support (Chapter 4)

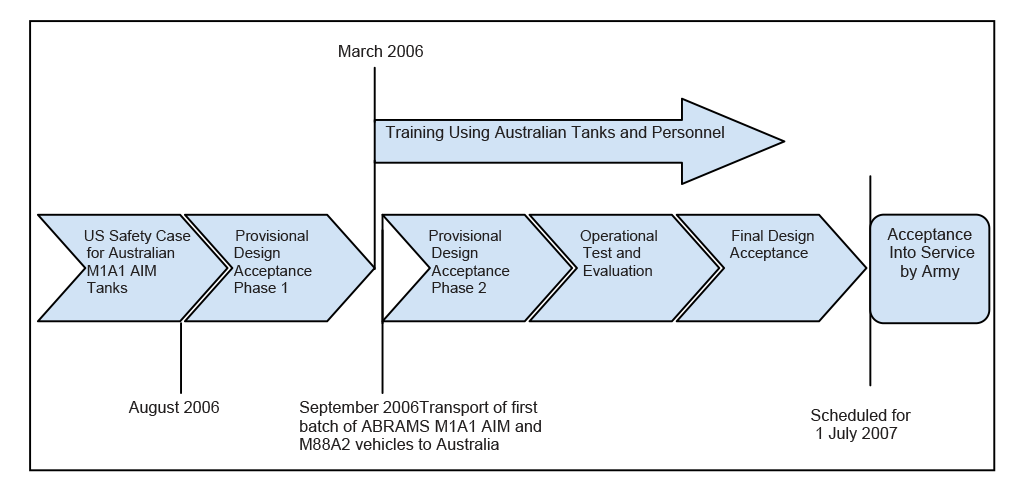

20. The engineering activities required to introduce a capability into service include Design Acceptance, Safety Management, Test and Evaluation, Configuration Management, Quality Assurance and Defect Investigation. The Design Acceptance of the tank and recovery platforms is being progressed using three key milestones: Provisional Design Acceptance Phase One; Provisional Design Acceptance Phase Two; and Final Design Acceptance, following an Operational Test and Evaluation report, certifying that there are no operational safety issues, and that Army Headquarters accepts the capability, which is planned for July 2007 (see Figure 1). At the time of audit fieldwork, neither Design Acceptance, nor Operational Testing and Evaluation had been completed.

Figure 1: Acceptance and test process for Australian ABRAMS Tanks

21. As of early 2007, the Australian Safety Case associated with the tanks had not been completed, prior to the start of training activities in Australia, using the first batch of delivered tanks. The DMO assessed that prior acceptance by the US Defense Forces of similar platforms, in conjunction with a managed hazard assessment log, and integrated instructor training by experienced US Defense Force instructors, mitigated the risks associated with using the delivered tanks in the absence of a completed Australian Safety Case.

22. In September 2006, the Minister for Defence announced that the options for transporting the ABRAMS included C-17 heavy airlift aircraft; amphibious ships; the Adelaide to Darwin rail network; and new tank transporter trucks. Trials associated with transporting the Australian ABRAMS, using the recently procured C-17 aircraft, have not yet been undertaken using Australian equipment.

23. The DMO advised the ANAO that it had maintained the ability to deliver the ABRAMS and M88A2 Hercules Recovery Vehicles by road to all the areas where Leopards would otherwise have been transported. In addition, Defence advises that the rail study has been completed and that the Request for Tender for heavy rolling stock has been released.

24. The maintenance concept for the ABRAMS will consist of two levels of repair; light and heavy. The ANAO has been advised that Army will continue to provide light maintenance to its tank capability in Darwin utilising uniformed tradesmen, and in Puckapunyal, using contracted staff, in keeping with the current arrangements for the Leopard AS1 tanks. Heavy maintenance will be offered to industry through the release of a Request for Tender for support service, in the second quarter of 2007. The stated aim is to deliver the best value for money for the Government. The DMO has advised the ANAO that there is no preference or mandate for any particular geographical location for this maintenance.

25. The Tank Driver Trainer, and six Advanced Gunnery Training Systems have been delivered and set to work within allocated budgetary and schedule requirements. The DMO estimates that the maximum costs associated with through–life support for these training capabilities will not exceed $4.8 million for the first seven years, with a planned life of type of 10 years. The DMO advise that the original equipment manufacturer recommended a specific Australian firm be engaged as the sole source provider for the simulator through-life support. The DMO subsequently engaged the recommended firm, on the basis that the original US based equipment manufacturer will remain the design authority for the simulators.

26. The planning and integrated nature of the training to introduce the new capability relied heavily on the ability to utilise simulation equipment. In addition, the strategy called for a progressive training plan to: train Australian instructors in the US; then train instructors in Australia; and finally, train equipment operators, maintainers and logisticians in Australia. The Project Office has effectively managed its training requirements as at the time of audit fieldwork, and has reportedly met individual training targets.

27. The increased operating costs associated with the new capability will limit the total distance the fleet can be driven in any one year, and reduce the use of training ammunition from the current use rate. These considerations have been taken into account when deciding to procure the capability, and simulation has been used, where possible, to reduce the costs associated with training. In addition, the use of 120mm training rounds will be reduced by the use of a .50 calibre main armament barrel insert, which will simulate the use of 120mm training rounds, thus increasing barrel life, and reducing the frequency associated with replacing main armament barrels.

28. The ANAO reviewed work undertaken by the DMO to ascertain the spare parts required to be held in physical inventory for the ABRAMS. The work undertaken considered the tanks geographical dispersion within Australia, planned track mileage and the intended operating terrain. As of early 2007, nearly all of the total items ordered had been shipped to Australia.

Defence and DMO response

29. The Department of Defence provided a response on behalf of the DMO and Defence. The Defence response stated that:

Defence considers that the acquisition of the Abrams tank capability through Project Land 907 has been an outstanding success, and is pleased that this ANAO audit reinforces that judgement. The Defence Materiel Organisation has successfully managed the delivery of the Main Battle Tank capability ahead of schedule and on budget.

It is noted that the audit has not raised any matters that the ANAO considered warranted a recommendation for action. All issues that have been noted in the report have been addressed or are being addressed. Release of a Request for Tender for through-life support has been delayed until slightly later in 2007, to allow time for the Defence Materiel Organisation to engage more fully industry. With respect to the battle management systems, Defence expects to have suitable satellite support in place by mid 2007.

Footnotes

1 The AIM programme constitutes a complete rebuild of the M1A1 tank, whereby they are disassembled, inspected, and where necessary refurbished, and reassembled. The process replaces an older style combat system with a digitised, integrated combat system.

2 In February 2007, the Minister for Defence announced that in addition to the 14 transporters being procured by the project, an additional four transporters had been ordered by the DMO for delivery by the end of 2007. The procurement of these transporters is being progressed as an Army Minor Project, through an extension to the existing contract.

3 The Defence Capability Development Manual 2006 defines ‘off-the-shelf' as a product that is available for purchase, and will have been delivered to another military or government body or commercial enterprise in a similar form to that being purchased at the time.

4 The combined estimated value of the series of FMS agreements supporting this project amounts to US$ 306.73 million.

5 The DMO advised the ANAO that the AIM process delivers a system that is more lethal, survivable and supportable, which includes on-board diagnostics and latest generation night fighting capability.

6 Defence advised the ANAO that the second FMS agreement includes the provision of off-platform equipment intended to be used by the Chief Information Officer Group in provision of the off-platform capability. However, errors in the FMS agreement have resulted in this equipment not being made available for sale at the stated price. Consequently, the full value of the FMS agreement will not be realised and Chief Information Officer Group must seek alternate methods for obtaining the equipment.

7 The new ABRAMS are battle proven, with high levels of crew survivability. The supporting M88A2 Hercules Recovery Vehicles are similarly operationally proven, and have been accepted into service by the US Military.

8 Defence define the fundamental inputs to capability as the standard list for consideration of what is required to generate ‘capability', comprising organisation, personnel, collective training, major systems, supplies, facilities, support, command and management.

9 The ANAO was advised that the compressed analysis period between First-Pass and Second-Pass Approval was primarily necessary to reduce the time Army was reliant on the obsolete Leopard 1 tanks in service, and to ensure staff availability for this project. The ANAO was also advised that Australia was able to access the US production line for M1A1 AIM tanks up until 2010.

10 The Operational Concept Document is the primary reference for determining fitness-for-purpose of the desired capability.

11 Functional Performance Specifications define critical performance attributes for the required capability, such as how fast it must travel, how much fuel it should use during specified operational uses, and how accurate its weapons systems should be.

12 The Test Concept Document provides the basis for DMO's development of the Test and Evaluation Master Plan, and is the highest level document that considers test and evaluation requirements.

13 The Acquisition Business Case provides an overview of the proposed capability option, and specifies key advantages of the preferred option, as well as costings, a time line for delivery, and a risk management assessment.

14 The ABRAMS M1A1 AIM tanks are a production model, with known operating and maintenance costs for the methods by which they are operated in the US Defense Forces. The analysis would have benefited from a more detailed analysis of costs associated with Life Cycle Costs as applied to Australian operating circumstances, and Test and Trials, however in the absence of a Test Concept Document, and in the environment of a fast tracked analysis period, Defence advise that this analysis was not possible in the time allocated for developing Second-Pass Approval documentation.

15 The Battle Management System provides, in addition to force distribution information, terrain data, location of known enemy forces, friendly locations, and the ability to send and receive messages and map overlays.

16 The DMO advise that it is capable, with software modifications, of supporting a Variable Message Format System in the future, should a system of this nature be procured for use as the preferred Defence Network Centric Warfare data communications system.

17 Defence advised the ANAO in June 2007 that the project to implement the off-platform capability has been re-scoped to provide a temporary L-Bank satellite service for one year and a PDS to investigate follow requirements including non-satellite solutions. That is, it does not have multiple stages. The estimate for temporary services is now July 2007.

18 The draw down payments to FMS suppliers are made through the non-interest bearing US Department of Defense Trust Fund Account, and occur on a bi-monthly basis in order to minimise the level of funds held in this account.

19 The Reserve Bank of Australia quoted exchange rate at this date was 0.7880, which equates to A$ 262.69 million.

20 Risks associated with transporting tanks by sea include the loss of the shipment through sinking, or damaged goods while in transit.

21 At that time, Defence maintained the capability to transport the vehicles by road, on specifically designed tank transporter vehicles.

22 Following the ANAO recommendation, the DMO did consider insurance as a risk mitigator for the second shipment of tanks to Australia, and made the decision that the low probability of loss did not justify the costs of insurance.

23 As at the time of fieldwork, Provisional Design Acceptance Phase two had not been granted.

24 The Safety Case for the M88A2 Hercules Recovery Vehicles was approved in November 2006. Of the managed safety issues identified, the ability to ford deep water (1.4m to 2.2m) presents a tangible risk to operators through suffocation. The M88A2 Safety Case recommends the use of night vision equipment as standard practice in reduced light scenarios.

25 The DMO advised the ANAO that the compressed acquisition timeframe was a key factor in accepting the tanks prior to having undertaken an Australian Safety Case, and that whilst the final Safety Case was not completed prior to the commencement of training, a risk analysis concluded that; based on the widespread use of M1A1 tanks by the US military, coupled with the significant amount of information available on the operation of the tanks during initial training for Australian instructors in the US, minimal risk was evident.

26 Defence advised the ANAO that the intention to the release the Request for Tender in May 2007 has been overtaken by the recent decision to delay the release of the Request for Tender until late 2007. This delay will be mitigated through consultation with industry towards the adoption of a better performance based approach.

27 Defence advised the ANAO that this cost does not include the cost of the platform FBCB2-BFT service. Estimated cost for the first year is $3.3 million.

28 A new tank driver training facility is being used to reduce the time required to qualify soldiers to drive the ABRAMS tanks. The project is also procuring six Advanced Gunnery Training System Simulators, which will serve to reduce the amount of live ammunition required to train for, and maintain, gunnery skills.